Step-by-Step Guide to Converting Your Vehicle to EV

Share

You'll begin by evaluating your vehicle's conversion potential, analyzing its weight, aerodynamics, and powertrain configuration. Next, choose an electric motor with high efficiency and power density, prioritizing motors with efficiencies above 90%. Then, select a compatible battery system, evaluating electrical architecture and performance requirements. You'll also design the electrical architecture, ensuring safe and efficient power flow. With careful planning and execution, you'll install the electric motor system, integrate the battery management system, and upgrade the vehicle's chassis and body. As you progress, you'll refine your understanding of the intricate details involved in this complex project.

Key Takeaways

• Assess your vehicle's compatibility for EV conversion, considering factors like age, make, and model, weight, aerodynamics, and powertrain configuration.

• Select a high-efficiency electric motor with power density above 2 kW/kg and an efficiency above 90% to ensure optimal performance.

• Design a battery system that balances energy density, power density, and cost, with a focus on lithium-ion batteries for optimal charging time.

• Ensure a safe and efficient electrical architecture design, incorporating high-power components, safety features, and high-voltage handling capacity.

• Update the vehicle's controller software and configure the battery management system to optimize torque for performance and energy efficiency.

Assessing Your Vehicle's Conversion Potential

When evaluating your vehicle's conversion potential, start by examining its fundamental characteristics, including its weight, aerodynamics, and existing powertrain configuration, as these factors greatly impact the feasibility and complexity of the EV conversion process.

You'll want to take into account compatibility factors, such as the vehicle's age, make, and model, to determine if it's a suitable candidate for an EV conversion. Your vehicle's history, including its maintenance records and any existing modifications, will also play a significant role in determining its conversion potential.

For instance, a vehicle with a heavy body or inefficient aerodynamics may require more powerful electric motors, which could increase the overall cost and complexity of the conversion. Similarly, a vehicle with a complex powertrain configuration may require additional engineering and fabrication, adding to the project's timeline and expense.

Choosing the Right Electric Motor

With your vehicle's conversion potential assessed, you're now tasked with selecting an electric motor that harmoniously integrates with your vehicle's unique characteristics and meets your performance expectations.

This pivotal step requires careful consideration of several key factors, including motor efficiency and power density.

You'll want to prioritize a motor with high motor efficiency, as it directly impacts your vehicle's overall energy consumption and range. Look for motors with efficiencies above 90%, as they'll help minimize energy losses and maximize your vehicle's electric range.

Power density, another critical factor, determines the motor's ability to deliver power relative to its size and weight. A high power density motor allows for a more compact design, reducing the overall weight and increasing the vehicle's agility.

When selecting a motor, aim for a power density above 2 kW/kg to ensure peak performance.

Selecting a Compatible Battery System

You'll need to carefully evaluate your vehicle's electrical architecture and performance requirements to specify a battery system that seamlessly integrates with your electric motor and meets your driving needs. This involves considering factors such as the motor's power output, your desired driving range, and the battery's voltage and capacity.

When selecting a compatible battery system, consider the Battery Life Expectancy, as it directly impacts your vehicle's overall performance and reliability. A longer battery life expectancy guarantees your EV remains efficient and reliable over time.

To optimize your battery system, you'll need to balance energy density, power density, and cost. Charging Time Optimization is also essential, as it affects your daily driving routine. Aim for a battery system that can recharge quickly, ideally within a few hours, to minimize downtime. Consider lithium-ion batteries, which offer high energy density, long cycle life, and relatively fast charging times.

Designing the Electrical Architecture

What electrical architecture will you design to efficiently distribute power from your battery system to the electric motor, guaranteeing peak performance and reliability in your converted EV?

As you configure your electrical architecture, you'll need to take into account the power distribution requirements of your vehicle. This involves selecting the right components, such as contactors, fuses, and wiring, to ensure safe and efficient power flow.

You'll need to design a power distribution system that can handle the high-voltage and high-current demands of your electric motor. This may involve using a combination of high-power electrical components, such as DC-DC converters and power inverters, to regulate voltage and current.

A well-designed electrical architecture will also incorporate safety features, such as overcurrent protection and thermal monitoring, to prevent electrical faults and ensure reliable operation.

Installing the Electric Motor System

Your electric motor system is the heart of your converted EV, and installing it requires careful planning and precision execution. This system includes the electric motor, motor controller, and power electronics, which work together to propel your vehicle.

To start, you'll need to design a system layout that guarantees efficient airflow, minimal electromagnetic interference, and easy accessibility for maintenance.

Next, you'll need to fabricate and install motor mounts that securely hold the electric motor in place while allowing for thermal expansion and vibration isolation. These mounts should be custom-made to fit your vehicle's specific dimensions and motor configuration.

Once the mounts are in place, you can install the electric motor, making sure it's properly aligned and secured.

Finally, connect the motor to the motor controller and power electronics, following the manufacturer's wiring diagrams and safety guidelines.

With the motor system installed, you're one step closer to getting your EV on the road.

Integrating the Battery Management System

As you integrate the battery management system, you'll need to select the right battery type for your EV conversion. Consider factors like energy density, power output, and charging cycles.

You'll also need to configure the hardware to guarantee seamless communication between the battery, motor, and charging system.

Next, you'll calibrate the software to optimize performance. This involves balancing parameters like state of charge, voltage, and temperature.

Battery Type Selection

Selecting the right battery type for your EV conversion project involves careful consideration of factors like energy density, power density, and lifespan, which ultimately determine the performance, range, and overall cost of your electric vehicle. You'll need to balance these factors to achieve your desired outcome.

When it comes to battery chemistry, you have several options. Here are a few common types:

| Battery Chemistry | Energy Density (Wh/kg) |

|---|---|

| Lead-Acid | 30-40 |

| Nickel-Metal Hydride (NiMH) | 60-80 |

| Lithium-Ion (Li-ion) | 120-150 |

As you can see, Li-ion batteries offer the highest energy density, making them a popular choice for EV conversions. However, they also come with a higher price tag. NiMH batteries offer a good balance between energy density and cost, while lead-acid batteries are more budget-friendly but heavier and less efficient.

When selecting a battery type, consider your specific needs and priorities. Do you need a high-performance battery for long road trips, or a more affordable option for short commutes? By weighing the pros and cons of each battery chemistry, you can make an informed decision for your EV conversion project.

Hardware Configuration Options

You'll need to design a hardware configuration that integrates a battery management system (BMS) to guarantee safe and efficient operation of your EV's battery pack. The BMS monitors and controls the state of charge, voltage, and temperature of each cell, ensuring the battery operates within a safe and best-suited range. When selecting components, consider sourcing high-quality cells, a reliable BMS, and efficient power electronics. Component sourcing is essential, as it directly affects the overall performance and reliability of your EV.

Cooling considerations are also important, as excessive heat can reduce the battery's lifespan and overall performance. You may need to design a thermal management system to regulate the battery's temperature, ensuring best-suited operating conditions. This might involve installing heat sinks, fans, or liquid cooling systems, depending on your specific requirements.

Software Calibration Process

With the hardware components in place, you must now calibrate the software to integrate the battery management system, ensuring smooth communication between the BMS and other vehicle systems. This process requires meticulous attention to detail, as even minor misconfigurations can compromise the entire EV conversion.

Begin by updating the vehicle's controller software to recognize the new BMS. This may involve code refactoring to guarantee compatibility with the existing system architecture. Next, configure the BMS to communicate with the vehicle's onboard systems, including the motor controller and charging system.

Torque optimization is vital at this stage, as it directly impacts the vehicle's overall performance and efficiency. Use specialized software tools to fine-tune the BMS settings, ensuring efficient energy distribution and minimizing energy losses.

Upgrading the Vehicle's Chassis and Body

To guarantee the structural integrity and stability of your vehicle, you must reinforce the chassis and body to accommodate the added weight and unique demands of an electric powertrain. This involves a thorough assessment of your vehicle's structural components, identifying areas that require strengthening to support the increased load.

Focus on Structural Reinforcement by upgrading key components, such as the frame rails, crossmembers, and suspension mounts. This may involve adding reinforcement plates, gussets, or welding in additional supports. Make sure that all modifications are carefully calculated to maintain the original vehicle's crashworthiness and safety features.

Additionally, consider Aerodynamic Modifications to optimize airflow and reduce drag. This can include installing air dams, spoilers, or side skirts to improve your vehicle's aerodynamic profile. These upgrades won't only enhance your vehicle's performance but also contribute to improved range and efficiency.

Configuring the Vehicle's Electrical System

As you configure your vehicle's electrical system, you'll need to create a detailed wiring diagram that accounts for every electrical component, making sure that each one is properly sized and connected.

You'll also select the right electrical components, such as fuses, circuit breakers, and relays, to guarantee safe and efficient power distribution.

Wiring Diagram Essentials

You'll frequently encounter complex wiring diagrams when configuring your vehicle's electrical system, and deciphering these diagrams is crucial to guaranteeing a successful EV conversion.

To navigate these diagrams, understanding the wiring standards and electrical notations used is vital. Familiarize yourself with the following key concepts:

-

Wiring Standards: Make sure your wiring diagrams adhere to industry standards, such as those outlined by the Society of Automotive Engineers (SAE) or the International Organization for Standardization (ISO).

-

Electrical Notations: Grasp the symbols and abbreviations used to represent components, connections, and wiring routes.

-

Component Identification: Learn to identify components, such as fuses, relays, and connectors, and their corresponding symbols.

-

Wiring Route Planning: Plan your wiring routes to minimize electromagnetic interference (EMI) and ensure safe, efficient power distribution.

-

Grounding and Bonding: Understand the importance of proper grounding and bonding techniques to guarantee electrical safety and prevent damage to your EV's electrical system.

Electrical Component Selection

Select the appropriate electrical components for your EV conversion by identifying the specific requirements of your vehicle's electrical system, including the voltage, current, and power ratings needed to guarantee safe and efficient operation. You'll need to determine the maximum electrical surge your system can handle to make sure your components can withstand it.

This will help you choose the right components, such as capacitors, resistors, and inductors, that can handle the electrical load.

When selecting components, prioritize power optimization to minimize energy losses and maximize your vehicle's range. Look for components with high efficiency ratings and low energy losses. For example, choosing a high-efficiency inverter can significantly decrease energy losses and heat generation.

Additionally, consider the operating temperatures and environmental conditions your components will face, ensuring they can withstand the demands of your vehicle's electrical system.

Circuit Protection Strategies

With your electrical components chosen, it's time to configure your vehicle's electrical system, focusing on circuit protection strategies to prevent damage from electrical surges, overcurrents, and short circuits. You'll want to guarantee your electrical system is designed to handle the unique demands of an EV, including high-voltage battery packs and powerful electric motors.

To achieve this, consider the following circuit protection strategies:

-

Fuse Ratings: Select fuses with ratings that match the maximum current-carrying capacity of your electrical components. This will prevent overheating and reduce the risk of electrical fires.

-

Arc Fault Protection: Implement arc fault protection devices to detect and interrupt electrical arcs, which can cause fires or damage to your vehicle's electrical system.

-

Overcurrent Protection: Install overcurrent protection devices, such as circuit breakers or fuses, to prevent damage from excessive electrical currents.

-

Short-Circuit Protection: Design your electrical system to detect and respond to short circuits, which can cause electrical shocks or fires.

-

Ground Fault Protection: Implement ground fault protection devices to detect and interrupt ground faults, which can cause electrical shocks or fires.

Testing and Refining the EV Conversion

As the converted vehicle roars back to life, your careful attention to detail during the testing phase is crucial in refining the EV conversion to guarantee smooth performance and maximum energy efficiency.

You've invested countless hours and sweat into this project, and now it's time to fine-tune your hard work.

During testing, you'll focus on performance tweaks and safety protocols. Monitor your vehicle's performance, taking note of any unusual sounds, vibrations, or temperature fluctuations. Check for signs of overheating, electrical issues, or battery drain.

You'll also need to confirm that all safety protocols are in place, including proper wiring insulation, secure battery mounting, and functioning safety shut-offs. Make adjustments as needed to optimize your EV's performance and ensure a safe driving experience.

Frequently Asked Questions

Can I Convert My Vehicle to an EV on My Own or Do I Need a Mechanic?

'As you commence on this electrifying journey, you wonder if you can tackle the conversion solo. While it's possible, be aware of DIY challenges and tool requirements that may leave you feeling overwhelmed, making a mechanic's expertise a wise investment.'

How Long Does a Typical EV Conversion Process Take to Complete?

When tackling an EV conversion, you'll face a conversion timeline that can span several weeks to several months, depending on your expertise and time constraints, requiring patience and dedication to complete.

Will I Be Able to Use My Existing Vehicle's Warranty After Conversion?

When you convert your vehicle to an EV, you'll likely void your manufacturer's warranty, losing manufacturer support; however, you can explore third-party warranty options or negotiate with the manufacturer for possible exemptions.

Are There Any Specific Safety Precautions I Should Take During the Conversion?

'When converting, you'll face risks like electrical shock, fire hazards, and exposure to hazardous materials. Protect yourself with personal protection gear, and make sure your toolbox has essentials like insulated tools and a fire extinguisher.'

Can I Convert a Diesel Vehicle to an EV or Only Gasoline-Powered Vehicles?

You can convert a diesel vehicle to an EV, but be aware of diesel limitations; the engine's higher compression ratio and fuel system may require additional modifications for electric motor compatibility.

Related Posts

-

Why Choose Solar Car Battery Charging Systems?

You're switching to a cleaner, more sustainable transportation option by choosing solar car battery charging systems,...

-

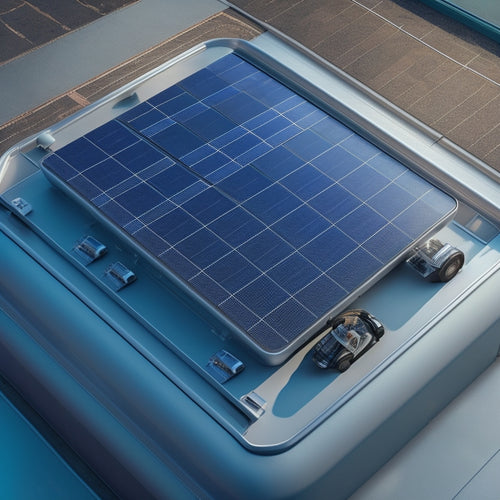

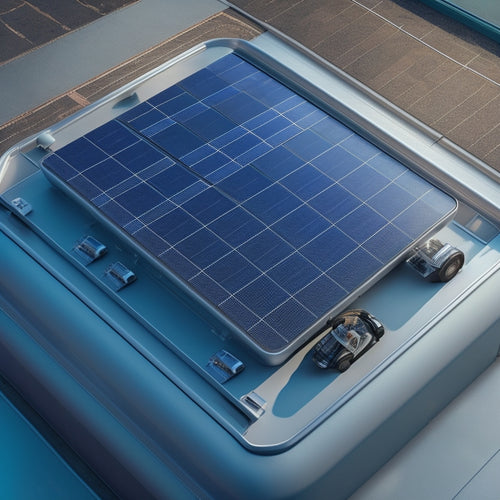

Top Solar Panels for Car Battery Maintenance

When selecting top solar panels for car battery maintenance, consider high-efficiency models with high wattage output...

-

What Role Do Unicycles Play in Urban Transport?

As you navigate through congested city streets, unicycles emerge as a viable solution, slashing carbon emissions by u...